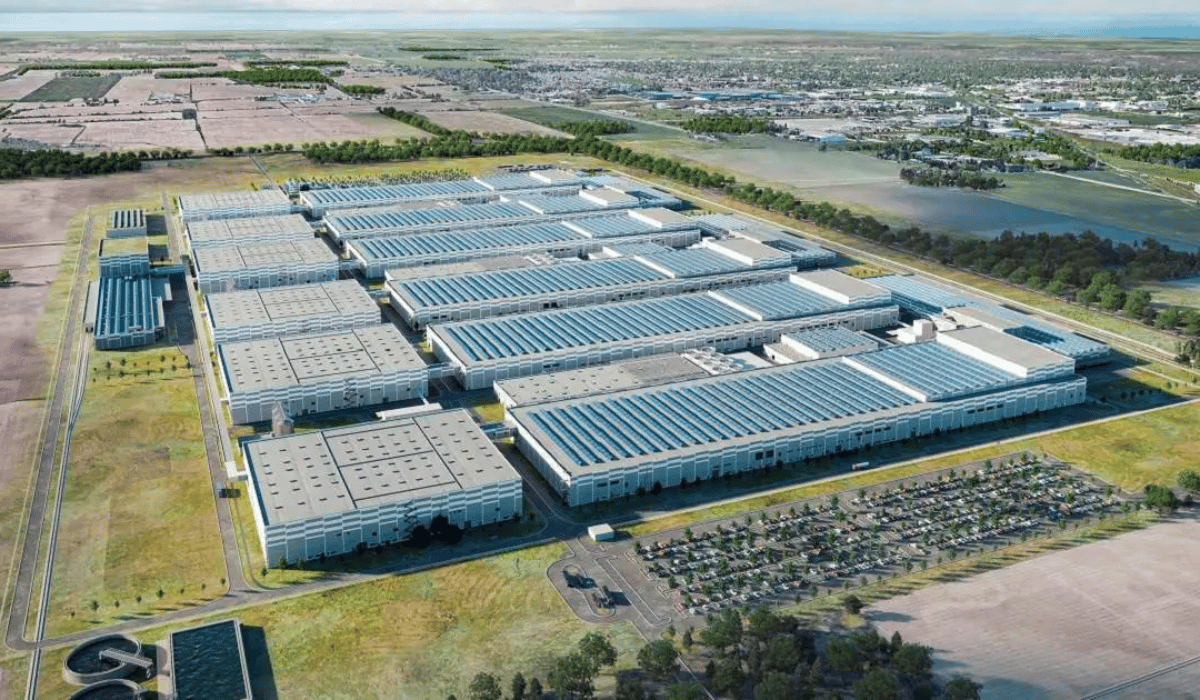

Organic India is reincarnating industrial architecture from its roots and branches. Conceptualised and built by Studio Lotus, the Integrated Production Facility for Organic India located in Lucknow, Uttar Pradesh. This campus consolidates the production, processing, and administrative functions of the wellness brand into a facility. This facility is not only sustainable in its material and energy consumption but also prioritizes the overall well-being of its occupants. The built fabric is a permeable brick structure with expansive open spaces around it. Such a context renders an earthly picturesque feel to the setting, something startling to find in manufacturing units. The project is a LEED Platinum-Rated Development which elucidates that the design is energy-efficient, occupant-friendly, and also benefits the planet.

The project is a sprawling campus located in Chinhat, an industrial area on the outskirts of Lucknow. The site is surrounded by scattered low-rise developments and small manufacturing plants amidst small barley and legume fields. Studio Lotus capitalized such a verdant backdrop to create an enriching environment for both the workers and administrators. Consequently, the built vocabulary of the facility has been articulated in brick and concrete. The design called for sleek lines and planar symmetry characterizing the façade design.

The building’s footprint is marked off by two sets of intersecting axes which create interior pockets that become courtyards, light-wells, and lawns.

Site Planning

The building’s footprint is marked off by two sets of intersecting axes. These axes create interior pockets that become courtyards, light-wells, and lawns. These internal spaces become spots for interaction and relaxation for the staff. The axes are also tilted at an angle to the site boundary. This results in the built-form creating large open spaces along the periphery. These outlying spaces accommodate staff parking, heavy vehicle manoeuvring, and off-loading, and recreational facilities. These are located towards the east, west, and north zones. They also position services in the south zone in accordance with Vastu principles.

Worker, visitor, pedestrian, and vehicular access has also been acutely segregated. The main entrance for the Production Wing being given from the western flank. This relatively private access provides workers with the opportunity to assemble before starting work. It also clears the driveway for incoming lorries. Preceded by a large lawn, the entrance along the western flank opens into a set of decontamination chambers for the workers. This thus allows them to systematically execute hygiene procedures before entering the Production Wing and subsequently the Raw Materials section.

Planning – Production and Processing Facility

The Production Wing has been designed to ensure seamless transfer of raw material to individual processing units. It also took care of their subsequent move to the packaging department. The Raw Materials section is a triple-height space. Accordingly, it comes with a sophisticated pulley system installed to move goods to the top floor. From here the goods then move laterally to the processing units. The processing units are housed in modular rooms that are 3 m wide each, each designed to specification for the machinery housed within. The goods are then moved through a top-down processing system. They have preliminary steps like sorting and drying executed at the topmost floor. They also have more sophisticated secondary functions executed on the ground and first floor.

This movement of goods from the Eastern to the Western side of the site marks the production line, forming the functional spine of the facility.

The goods, having moved down the production line, are loaded onto a conveyor belt. This further connects the Production Wing to the Finished Goods Block. This is located towards the Northern end of the site. Here, inspection and packaging of the processed goods gets done making them ready for dispatch. The Finished Goods block — which is adjacent to the Quality Control Department — opens into a driveway with restricted access. This then allows moving of approved goods off-site without disturbing the functions of the rest of the facility. This movement of goods from the Eastern to the Western side of the site thus marks the production line. This in turn forms the functional spine of the facility.

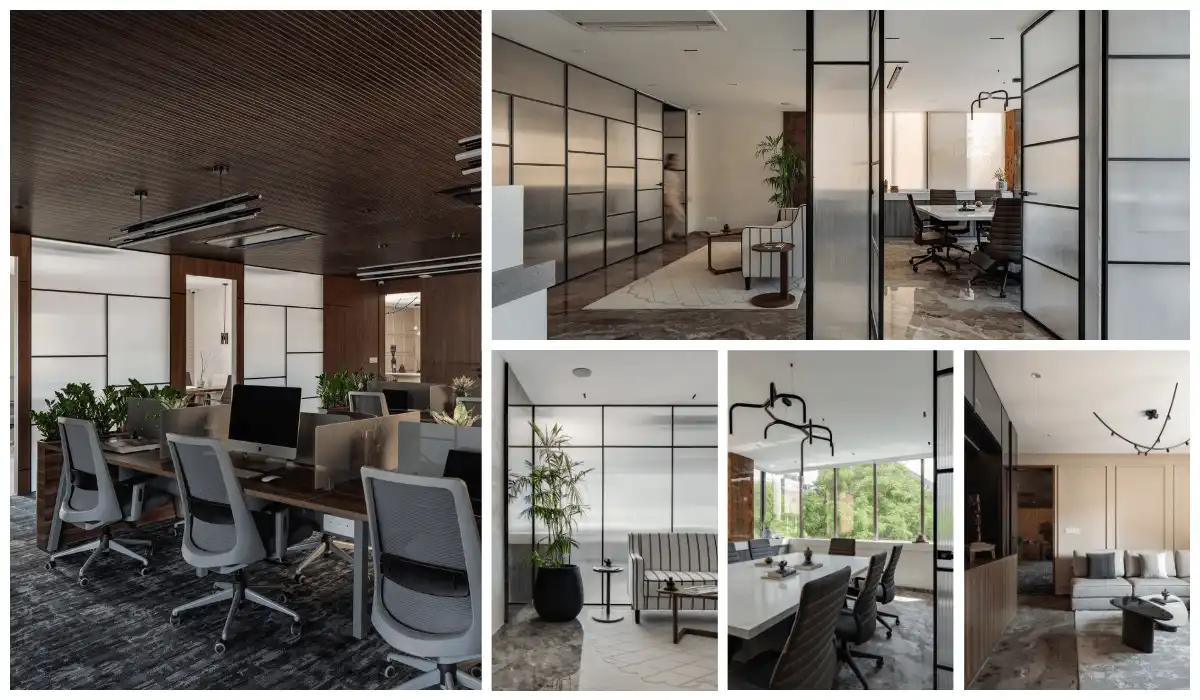

Planning – Administrative and Recreational Spaces

The spaces supporting the administrative functions of Organic India complement the site’s functional spine. These extend from the Finished Goods block to the drop-off for the Raw Materials section. The built vocabulary of these blocks is porous and composite, as compared to the monolithic appearance of the processing wings. To the eastern end is the Experience Centre for Organic India, a two-storey space wrapped in a tessellated brick screen. The facility’s amphitheatre and temple precede this centre — the three, in conjunction, mark the visitors’ zone of the facility. The office spaces, expressed in a similar vocabulary, about the Experience Centre — extend towards the west in a linear configuration. They also extend towards housing the Finance, HR, and Sales departments. Ancillary functions for the administrative staff are located towards the end of the Administrative Block. They consist of meeting rooms, a gym, and the cafeteria.

The administrative spaces of the facility wrap around a large lawn, facing north. A large tree retained on-site stands in this lawn. Christened the Bodhi Tree for the campus, this pays homage to Organic India’s commitment to mindfulness for the self and for the community. The administrative spaces, through numerous balconies and box windows, look into this lawn. The provision of nooks and perches along the building envelope thus lends a meditative quality to the workspaces.

Sustainability and Energy-Efficiency

The design scheme of the facility imbibes local influences to create a sustainable built environment. The primary among these being the use of bricks as the primary infill material. Left exposed, the facility’s brick shell harkens to the regency structures of colonial Lucknow. Bricks are also locally available due to the abundance of labour-intensive kilns and the availability of pliable clay. This lowered the carbon footprint of the campus. The fenestration strategy, in turn, has been devised to provide an optimal wall-window ratio to each zone. The processing blocks have limited ingress of light, facilitated through skylights and northern lights, to prevent spoilage of goods. On the other hand, high ingress of light has been enabled in the administrative blocks. This in turn helped lower dependence on artificial means of lighting.

The interstitial open spaces on campus further aid climate control in multiple ways. Passive cooling of the blocks enabled the stack effect. The abundance of open spaces and limited hardscaping also increases the potential for recharging the groundwater table. The design of the facility also ensures the channelling of surface run-off for reuse and recycling of grey-water discharge. The result has been the reduction of potable water consumption by more than half of the initial demand.

The design scheme utilizes a gamut of passive cooling techniques. This includes terracotta filler slabs in the large-span spaces and recessed openings to cut out solar glare. The construction of this facility used materials of which recycled material count for over one-tenth of the total. The project won a LEED Platinum rating as a result of these initiatives amongst others.

Impact

Since the dawn of the Industrial Revolution, the design of production facilities has largely been cold and dreary. Little attention was paid to aspects like energy efficiency and the psychological needs of the workers. Studio Lotus has thus been able to create a stellar industrial campus that speaks of sustainability in every respect. The design with expansive open spaces and permeable built fabric, ensured focus on community and introspection. It also prioritized the workers’ safety and comfort over all else. This created an architectural template for all future properties for the company.

Studio Lotus

Website: www.studiolotus.in

E-mail: business@studiolotus.in, media@studiolotus.in

Contact: 011-4057 0808

Biltrax Construction Data is tracking 17000+ projects on its technology platform for its Clients. Email contact@biltrax.com to subscribe and generate business leads.

Discover more from Biltrax Media, A Biltrax Group venture

Subscribe to get the latest posts sent to your email.