Steel is still the preferred construction material, and new technological advancements are guaranteeing that structures are becoming better and safer. Steel is used in all aspects of architecture and building construction these days. There has been a changing culture in the lifestyle and infrastructural development of Modern India. The range of applications and utilisation of stainless steel has been following an organic trajectory since the time it was introduced to the world of construction in the 1920s. Steel aids in practical and functional construction, while also providing aesthetic value to buildings.

What is the significance of steel?

With the development of steel as a construction material, the notion of unsupported towering buildings came to life. In India, industry and infrastructure are the primary drivers of steel structural demand. Steel structures are the most energy, material, and labour efficient. Steel was thrust to the forefront of architecture as a result of this. Structures made of steel are currently recognised for their variety of shapes and architectural expressiveness, which make them more dependable than other types of structures.

Steel as a construction material provides for additional floors per overall height of the structure. Steel beams do not need to reach as deep as concrete beams to support the floor plate, hence the structure is more structurally efficient. Steel may also support lighter sections, allowing for the same load-bearing capability per level. This provides for up to 1.5 times more floor area in the same exterior height of the structure. When opposed to concrete, the column dimensions are smaller, allowing for a larger habitable area.

Steel Industry in India

Steel is one of India’s most important sectors, accounting for little more than 2% of GDP. By 2030–2031, the steel industry would require Rs 10 lakh crore in additional capital expenditure and 27 GW of electricity supply to meet anticipated capacity development and demand growth. The steel industry in India employs around 25 lakh people in direct and indirect occupations, and is predicted to increase to 36 lakh jobs by 2031, clearly contributing to the country’s economic development in both direct and indirect ways (economic value addition) (helping to build purchasing power through employment generation).

Over the years, the government has implemented a number of programmes aimed at fostering growth in the domestic steel sector, including infrastructure projects such as rail track electrification, dedicated freight lanes, high-speed rail projects, affordable housing, and power transmission. Over the last few years, the Ministry of Steel has also established measures to strengthen the sector. The Domestically Manufactured Iron and Steel Products (DMI & SP) Policy was created by India’s government in 2016 to provide priority to indigenous products in government procurement.

The policy applies to both iron and steel products, as well as capital items used to manufacture them. It also establishes a minimum level of value addition for high-strength grade (for products) and individual capital items. Complaints must be resolved in a timely manner, according to the policy (audits and further inspection to be conducted by procurement agencies). The government also launched the Steel Import Management System (SIMS) in November 2019 as a sophisticated and granular source of data on imports, including sources, end uses, product categories, and grades of steel imported into India by the government, the steel industry (producers), and steel consumers (importers) for effective policy interventions.

Using digitisation in mining to secure raw materials and increase production, promoting a shift to environmentally friendly steel industry, expanding the capabilities of domestic steel plants, enabling supply through best-in-class greenfield capacity addition, and establishing value-adding steel clusters are just a few of the planned initiatives.

Advantages of steel

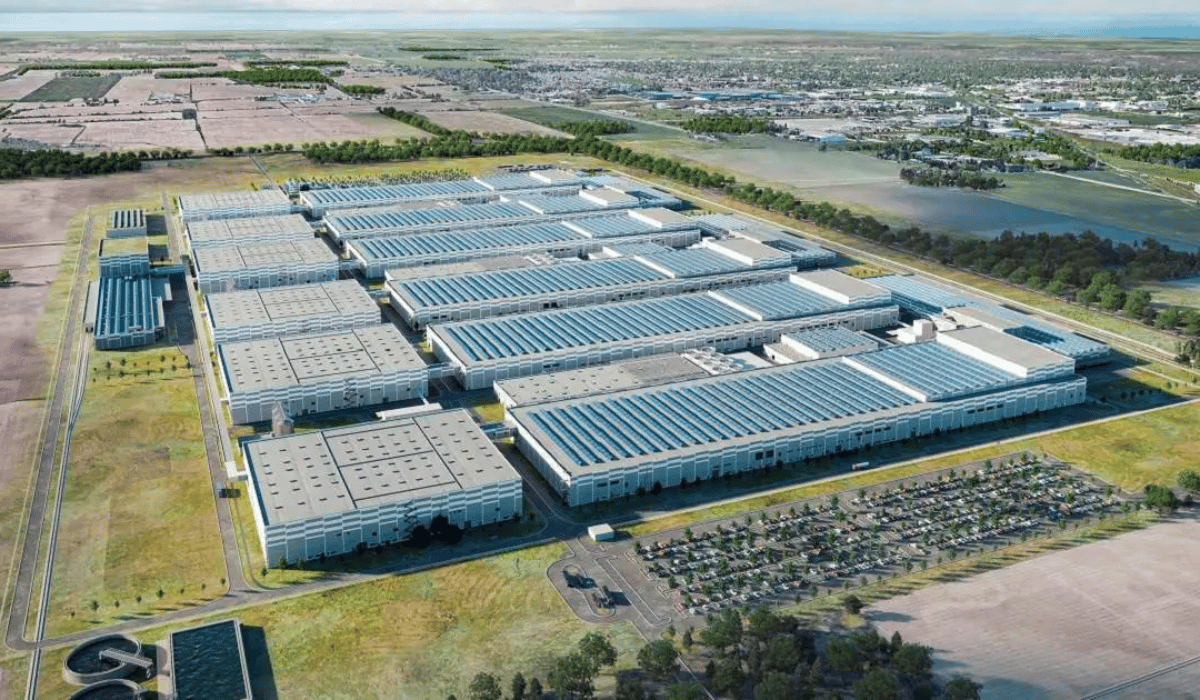

Steel construction has unrivalled advantages. For example, when compared to RCC, it has a higher strength-to-volume ratio, is faster to construct, and allows for lighter foundations. This leads to a financial benefit over civil construction, as well as taking up less area and providing well-planned and bigger floor spans with a lot of open space. This is shown in the Rupa Renaissance, a building in the Navi Mumbai area where the most modern steel structure is intended for a cheap construction cost while maintaining the same architectural framework.

Composite steel enhances the structure’s capacity to transmit loads more effectively and helps to make it stronger than traditional rigid materials. Composite steel bridges the gap between RCC and composite steel constructions by combining the qualities of steel and concrete. To offer a structural building with superior lateral stiffness to handle wind loads, high-rise steel frames constructed of H-columns and H-beams, as well as cross-bearing walls, are included. The building’s strength is increased by using hot-rolled steel sections made of higher-grade steel. Because of the increased per-floor strength, the total core structure may be lighter. Steel aids in the creation of huge internal areas with no columns, which is especially beneficial for open-plan offices and halls.

As opposed to concrete, steel frames provide enough headroom to allow all service conduits. Another key benefit of steel structures is that they allow for speedier construction, while the pre-fabricated framework offers superior quality control. Unlike the concrete building process, pre-engineered design lowers time, on-site activity, materials, and labour while inflicting the least amount of damage.

As steel structures can be erected in a shorter time frame, the faster edge given in building construction results in economic advantages. Because steel frames are lighter, the load on the foundation is greatly decreased. This is important to remember since the foundation of any high-rise structure is often made up of concrete piers or piles buried in the earth. In comparison to concrete frames, it is also comparatively straightforward to make later adjustments or floor strengthening in steel frames.

Steel has dominated the building industry for almost a century as a result of these benefits. It has grown more adaptable in its use. Steel can be integrated with other high-elastic-limit and structural-strength building materials such as glass, cold-rolled, and galvanised flat goods. Steel is no longer a labour-intensive business, and the bulk of the building materials used in India are 100% recyclable. Steel’s durability, adaptability, and sustainability make it ideal for a variety of construction applications, as observed and employed by Access Architects, who plan to use steel in the majority of their projects. The steel industry has seen the adoption of new steel modular frame systems on building sites as the era of connectedness with technology has progressed. Steel is viewed as a good fit for modular construction, and recent technological advancements have boosted its popularity. This need will only continue to climb as the world’s population grows and cities expand.

Conclusion

Steel has dominated the building industry for almost a century as a result of these benefits. It has grown more adaptable in its use. Steel can be integrated with other high-elastic-limit and structural-strength building materials such as glass, cold-rolled, and galvanised flat goods. Steel is no longer a labour-intensive business, and the bulk of the building materials used in India are 100% recyclable. The steel industry has seen the adoption of new steel modular frame systems on building sites as the era of connectedness with technology has progressed. Steel is viewed as a good fit for modular construction, and recent technological advancements have boosted its popularity. This need will further increase as the world’s population grows and cities expand.

Sources:

- Steel structures : Changing the face of Indian Architecture

- Steel sector looks to increase production, enhance raw material security in 2022

- Rewriting the growth story for India’s steel industry

- How is steel architecture changing the face of India

Disclaimer: The information contained herein have been compiled or arrived at, based upon information obtained in good faith from sources believed to be reliable. The opinions expressed within the content are solely the author’s and can be subject to change. The image featured in this article is only for illustration purposes. If you wish the article to be removed or edited, please send an email to editor@biltrax.com

Discover more from Biltrax Media, A Biltrax Group venture

Subscribe to get the latest posts sent to your email.